FSS

Tank Mix Grain Protectant Applicator

Features

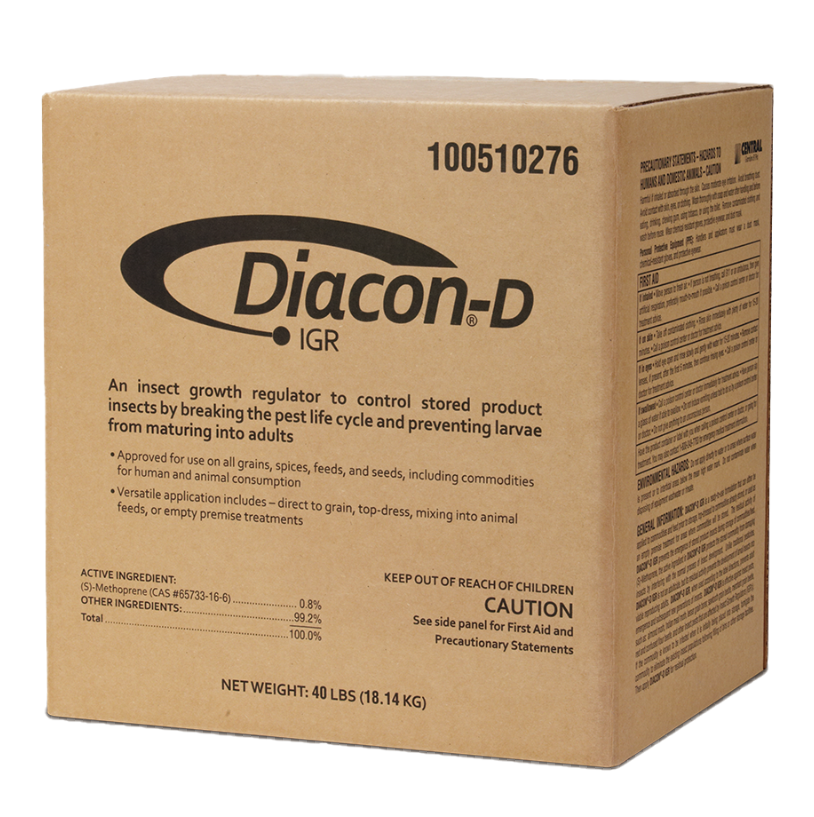

A cost-effective solution that applies pre-mixed grain protectants like Diacon® IGR, Gravista®, Centynal™ EC directly onto moving grain

300 gallon capacity treats up to 60,000 bushels in a single run

Self-priming diaphragm pump with 110-volt power for easy setup and operation

Recirculating system ensures uniform chemical mixing for consistent application

Magnetic spray nozzle attaches securely to conveyors and removes easily for cleaning

Handles most conveyor belt speeds from 5,000 to 25,000 bushels per hour

Cost-effective alternative to injection systems, customizable upon request

Product Overview

The 300-Gallon Tank Mix Application System is built for grain elevators, flour mills, and storage facilities that need efficient, on-belt treatment at high throughput. With a calibrated output of 5 gallons per 1,000 bushels, this system can treat up to 60,000 bushels in a single run, helping reduce shrink, dockages, and insect-damaged kernels (IDK) by up to 18%.

Powered by a self-priming diaphragm pump (110V) and a recirculating design for uniform mixtures, the system ensures consistent applications. The magnetic spray nozzle attaches securely to conveyors, is easy to clean, and customizable for facility needs.

At just $2,464 per base unit, this system offers one of the most affordable ways to apply leading grain protectants including Gravista®, Diacon® IGR, Centynal™ EC, Centynal™ Synergized, PBO-8®, and more.

Customer Reviews

- Choosing a selection results in a full page refresh.